Set-up of the F*Race 2 ABS system

01 September 2025HARNESS

MPORTANT SAFETY NOTICE

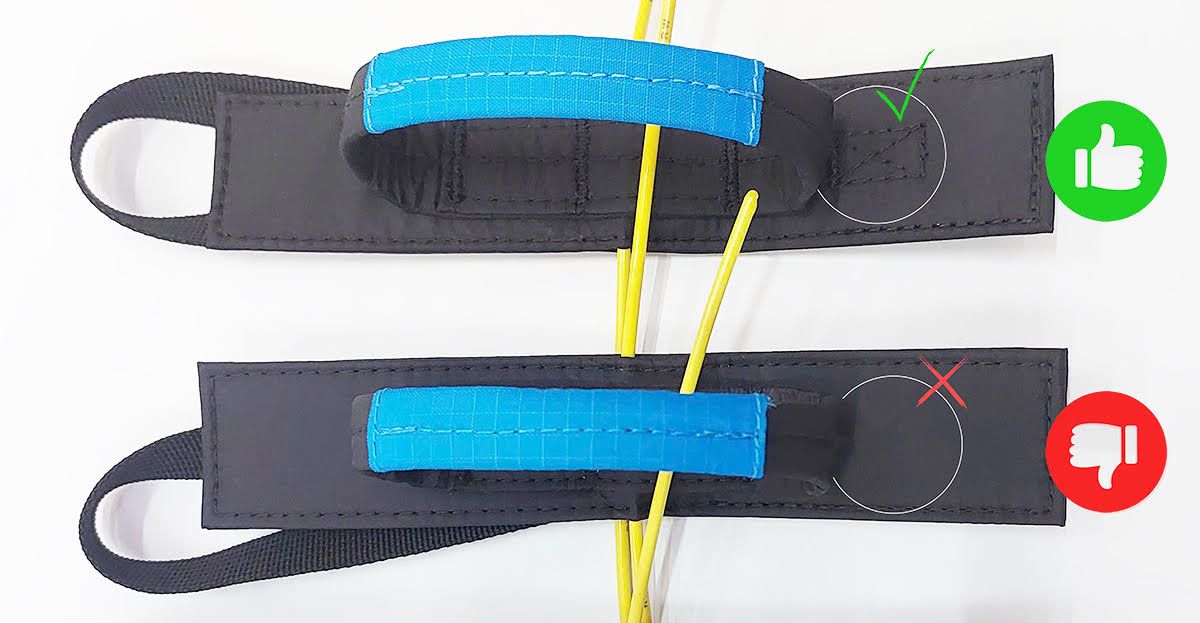

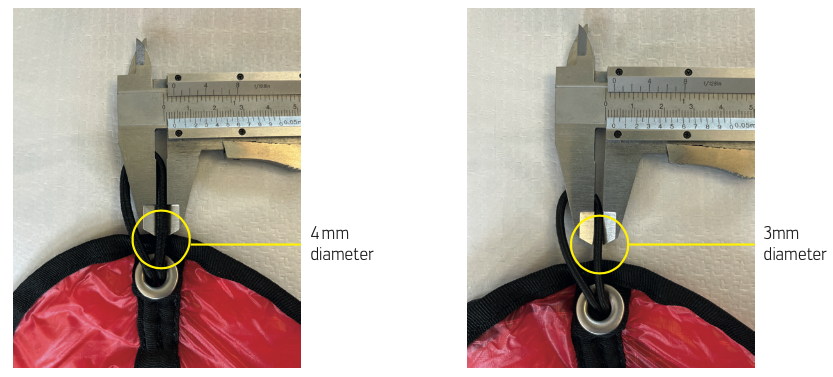

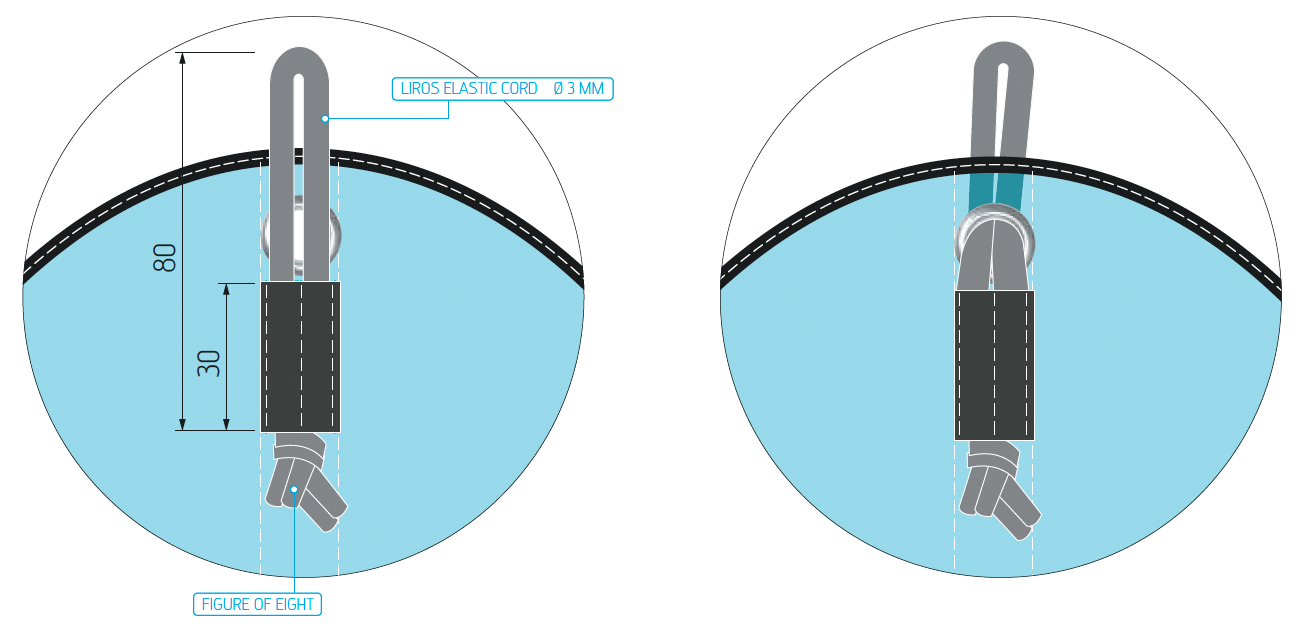

ABS LINE CONNECTION WITH THE CHEST STRAP

Overview

The F*Race 2 is delivered with an adjustable ABS system. It's made from a dyneema line in which the top loop needs to be in the correct position at all times.

The dyneema line is part of the overall red loop inner diameter, and therefore to the stability of the connection with the toggle (the coloured metallic part which goes through the loop) and the chest strap. It prevents the toggle from getting out of the loop inadvertently.

Current situation and upgrade

For all F*Race 2 harnesses delivered until now, the dyneema ABS line is assembled with a lark's head knot around the red chest strap loop. There may be a possibility, although minimal, that it may slip out of the red loop thereby widening its opening and allowing the toggle to escape when the chest strap is not in tension. We require F*Race 2 pilots to check the position of this loop, and modify its connection as shown below. This new ABS connection is also implemented in all new F*Race 2 harnesses in production.

Ozone - Front Container Rescue Handle Recall

10 July 2025HARNESS

Information about Parachute Containers: Arrow P, Arrow & Hawk

04 July 2025HARNESS

Problem

Some reserve parachutes are not sufficiently fixed in the very spacious harness container. These can move, twist with the connecting line or open. This can make it difficult or impossible to deploy the reserve parachute.

Check and safety measures

Users of the aforementioned harnesses are requested to open the harness container and check the position of the reserve parachute container. If the reserve parachute container is insufficiently fixed and can change its position in the harness container (rotate, tilt, swing back and forth), there is a safety problem. The harness should not be used in this configuration. Instead, users should contact the manufacturer for a technical solution (https://niviuk.com/de).

Safety message from the manufacturer

Niviuk is requested to publish a safety message including a solution for repair/rework in a timely manner

Safety note ICARO tandem spreaders

28 June 2025TANDEM

IMPORTANT INFORMATION regarding Icaro TANDEM SPREADER

We have received feedback from a customer that problems have occurred with the tandem spreader. The reason is that the edges of the metal fitting on the carbon bar are too sharp, as they have not been deburred sufficiently. As a result, the webbing of the spreader can be damaged and, in the worst case, could be cut.

Carabiners corroded by penetrating oil

15 June 2025

Carabiners will get corroded by this lubricant!

https://flyappi.org/media/commented_videos/videos/WhatsApp_Video_2025-06-15_at_12.19.57_1.mp4

Carabiner Woody Valley Zicral Camp Automatic Fatigue Failure!

15 June 2025

Safety Note: Kortel Design - Kanibal Race II, Kanibal Race ST - Rescue handle entanglement

31 March 2025HARNESS

Supair Pixair 1 harness - Rescue container

28 March 2025HARNESS

Sup'air PARACHUTE BRIDLES issue

09 April 2023

Possible absence of a safety seam on solo or tandem parachute bridles.

SAFETY NOTICE: GIN G-LITE RESCUE PARACHUTE

01 November 2022

Issue with the rubber bands closing the inner bag of the G-Lite rescue parachute

Skywalk Chili 3 lines

19 October 2022

Skywalk Salsa reserve container rubber loop issue

04 October 2022

DHV accident investigation: issue with long connection belt between reserve handle and pod

12 December 2021

SAFETY WARNING – PANORAMA 41

12 October 2021

SAFETY CRITICAL ALERT : TANDEM SPREADERS

12 October 2021

SAFETY CRITICAL ALERT : RUPTURE IN FLIGHT OF THE MAIN CARABINERS

12 October 2021

SAFETY CRITICAL ALERT : Woody Valley XR7

12 October 2021

SAFETY ALERT : TANDEM GLIDER SUPAIR SORA 2 size 42 - ATTACHMENT POINTS RUPTURE

12 October 2021

SAFETY ALERT : Safety Notice Quick-Out Carabiner

12 October 2021

SAFETY ALERT : NEO BODY HARNESS

12 October 2021

SAFETY ALERT : OZIUM HARNESS

12 October 2021

SAFETY ALERT : Supair leaf tolerance

12 October 2021

SAFETY ALERT : Exoceat harness

12 October 2021

SAFETY ALERT: Charly Carabiner

12 October 2021

SAFETY ALERT: Accidental opening of the ventral automatic buckles in flight

12 October 2021